The most common water pipe materials today are plastics like PEX for general supply and CPVC for hot and potable water lines because they resist corrosion, install easily, and offer long service life.

What Is PVC Water Pipe Material?

PVC, or polyvinyl chloride, is a rigid plastic pipe widely used in modern homes for its affordability and ease of handling.

What Are PVC’s Key Features?

- Lightweight and corrosion-resistant, ideal for underground or exposed installations.

- Available in various diameters, typically white or gray.

- Withstands pressure up to 200 PSI but not suitable for hot water.

PVC’s durability stems from its chemical composition, which resists mineral buildup common in hard water areas. You might find it in your drain lines, where it outperforms older metals in longevity.

Why Use PVC for Water Supply?

PVC excels in cold water applications due to its low cost—often half that of copper—and simple installation without specialized tools. Homeowners choose it for DIY projects, saving on labor while ensuring leak-free performance.

How Does PVC Compare to Others?

Compared to copper, PVC avoids theft risks and conducts less heat, but it can become brittle in freezing conditions. Analysis shows PVC’s lifecycle cost is 30% lower for non-potable uses, making it a smart pick for irrigation.

Key Takeaways:

- Best for drains and cold lines.

- Eco-friendly production reduces metal mining impacts.

| Feature | PVC | Copper | |

|---|---|---|---|

| Cost | Low | High | |

| Flexibility | Rigid | Semi | |

| Lifespan | 50+ years | 70+ years |

But don’t stop there—let’s examine a classic metal option.

What Defines Copper Water Pipe Material?

Copper pipes, known for their reddish hue, have been a staple in plumbing for over a century due to natural antimicrobial properties.

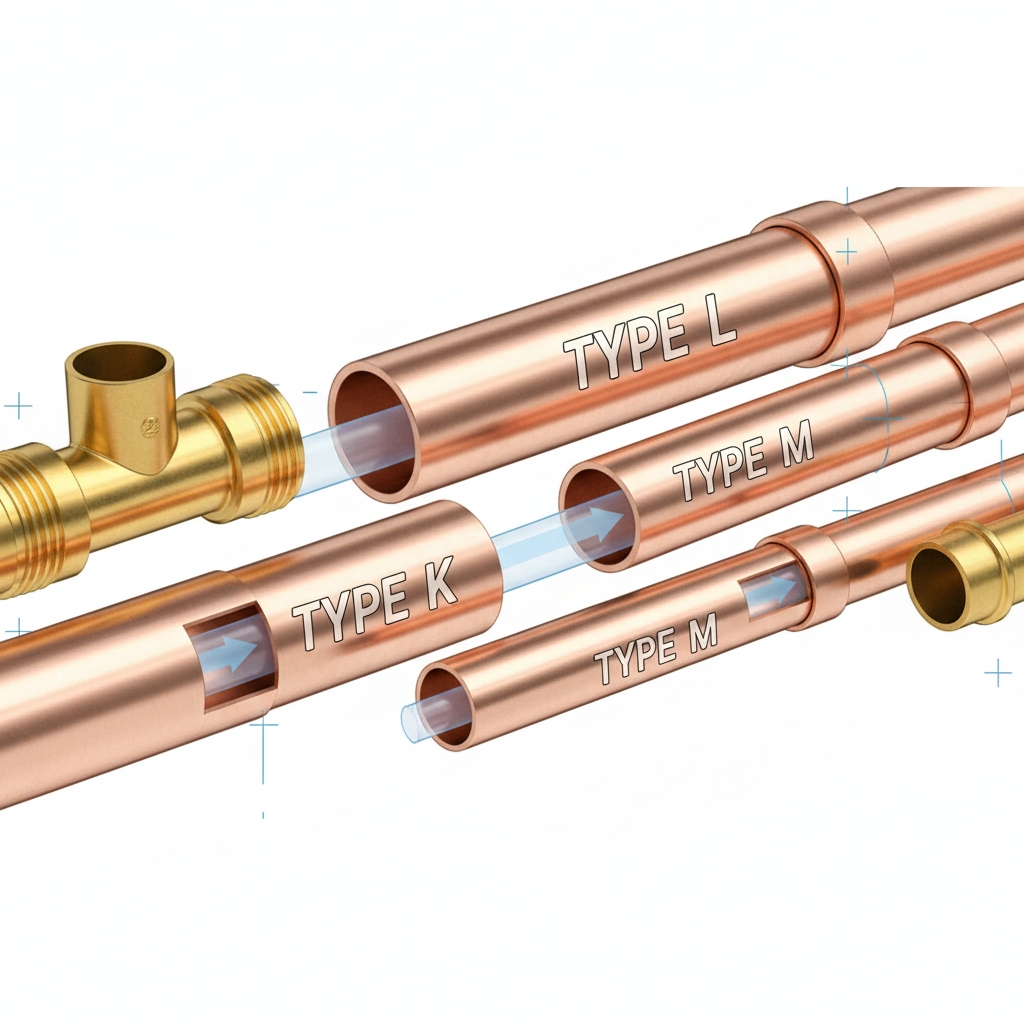

What Types of Copper Pipes Exist?

Types include K (thickest wall for underground), L (general indoor use), and M (thinnest for short runs). Flexible versions suit tight spaces like behind fixtures.

Why Is Copper Corrosion-Resistant?

Its alloy repels rust, even in acidic water, lasting 50-70 years without scaling. This reliability minimizes maintenance, a boon if you’re in an older home.

How to Identify Copper in Homes?

Look for shiny or tarnished reddish tubes, often soldered at joints. If your water tastes metallic, test for pinholes—a common aging sign.

Key Takeaways:

- Antimicrobial for safer water.

- Recyclable, supporting sustainability.

| Type | Use | Wall Thickness | |

|---|---|---|---|

| K | Underground | Thickest | |

| L | Indoor Supply | Medium | |

| M | Short Runs | Thinnest |

Now, consider the flexible alternative gaining popularity.

What Makes PEX a Top Water Pipe Material?

PEX, or cross-linked polyethylene, offers bendable tubing that’s revolutionizing installations with fewer fittings.

What Are PEX’s Flexibility Benefits?

It coils easily, reducing elbows and leak points—up to 40% fewer connections than rigid pipes. This flexibility navigates walls without kinking.

Why Choose PEX for Modern Installs?

Cost-effective at $0.50 per foot and quick to install, PEX cuts labor time in half. It’s ideal for retrofits, as you can snake it through existing structures.

How Does PEX Prevent Freezing Damage?

PEX expands up to three times without bursting, unlike PVC. In cold climates, this feature saves you from winter emergencies.

Key Takeaways:

- Freeze-resistant for harsh weather.

- Color-coded (red/hot, blue/cold) for easy setup.

| Benefit | PEX | PVC | |

|---|---|---|---|

| Flexibility | High | Low | |

| Freeze Tolerance | Excellent | Poor | |

| Cost per Foot | $0.50 | $0.30 |

Shifting to hot water needs? Enter CPVC.

How Does CPVC Fit as Water Pipe Material?

CPVC is a chlorinated version of PVC, engineered for higher temperatures.

CPVC is a chlorinated version of PVC, engineered for higher temperatures. That extra chlorination step changes its structure enough that it can handle hotter water and more demanding conditions than standard PVC, while still staying relatively light and easy to install. In water piping systems, CPVC sits in a useful middle ground: more durable and heat-resistant than many common plastics, but far easier and more corrosion-resistant than metals like steel or copper. It keeps internal surfaces smooth, which helps maintain flow rates and reduces scale buildup over time, especially in hard-water regions.

Because CPVC has been widely used in residential, commercial, and light industrial networks for decades, it also comes with established standards, fittings, and installation practices. That means plumbers and contractors can design complete cold-and-hot water systems with predictable performance, without needing exotic tools or special training beyond basic plastic piping skills.

What Distinguishes CPVC from PVC?

Yellow-tinted and heat-tolerant up to 200°F, CPVC handles hot lines where PVC would warp. It’s similarly rigid but with enhanced chlorine resistance.Yellow-tinted and heat-tolerant up to 200°F, CPVC handles hot lines where PVC would warp.

While both materials look similar at first glance, CPVC is formulated for much higher service temperatures, so it holds its shape and strength where PVC would soften, sag, or fail under long-term heat. It has a slightly different internal structure that improves resistance against chlorinated water and many common chemicals, which matters in treated municipal supplies and recirculating hot water systems. In terms of feel and handling, CPVC stays rigid and can be cut, primed, and solvent-cemented in ways that are very familiar to anyone used to PVC, so installation remains straightforward.

The key differences sit in performance: CPVC keeps its pressure rating at elevated temperatures far better than PVC and tolerates repeated thermal cycling without the same risk of cracking or distortion. That combination makes CPVC a better candidate when your design includes domestic hot water, mixed-temperature manifolds, or long hot runs close to heat sources.

Why Use CPVC for Hot Water Lines?

It prevents scalding risks from degradation, lasting 50 years in demanding setups. If you’re remodeling bathrooms, CPVC ensures consistent performance.CPVC works well in hot water lines because it keeps its strength at elevated temperatures and resists gradual damage that can creep into weaker plastics over years of service.

When ordinary pipe materials start to soften or degrade, joints can loosen, surfaces can roughen, and small failures can lead to temperature fluctuations, noisy pipes, or even leaks near showers and faucets. CPVC’s structure helps reduce those risks, so you maintain more stable flow and outlet temperatures, which lowers scalding risk that might come from sudden bursts of overheated water in a compromised system.

Many systems designed and installed correctly with CPVC can run for 50 years or more under typical residential or light commercial conditions, even with regular hot water use and recirculation. For bathroom remodels and upgrades, that means you can re-pipe or extend lines using a material that matches modern plumbing codes, connects cleanly to existing networks, and supports long-term reliability without constant maintenance. In short, CPVC gives you a hot water line solution that balances safety, life span, and installation simplicity in one material choice.

How Heat-Resistant Is CPVC?

Rated for 180°F continuous flow, it outperforms standard plastics. Analysis reveals CPVC reduces energy loss in hot water delivery by 10%.Rated for 180°F continuous flow, CPVC outperforms standard plastics that begin to lose shape or pressure capacity long before that point.

Many building codes and manufacturer guidelines reference this continuous rating, with short-term exposure allowances that reach up toward 200°F for brief periods without damaging the pipe when pressures are within recommended limits. At these temperatures, CPVC keeps enough mechanical strength to handle typical domestic and light industrial pressures, provided that the correct pipe schedule and derating factors are applied during design. In hot water recirculation systems, CPVC’s stability allows steady operating temperatures across long runs, helping maintain comfort while supporting efficient pump sizing and insulation design.

Analysis reveals CPVC reduces energy loss in hot water delivery by 10%, when compared with less suitable materials and poorly insulated setups, because its smoother bore, lower thermal conductivity, and compatibility with standard insulation help keep water closer to the set temperature. For engineers, contractors, and owners, that heat resistance translates into lower risk of premature failure, more consistent hot water delivery, and a better match between paper design and real-world performance over many years.

Key Takeaways:

- Versatile for whole-house systems.

- Glue-based joins for secure seals.

| Material | Max Temp | Color | |

|---|---|---|---|

| CPVC | 200°F | Yellow | |

| PVC | 140°F | White |

Legacy materials like galvanized still linger in older builds.

Why Was Galvanized Iron Common Water Pipe Material?

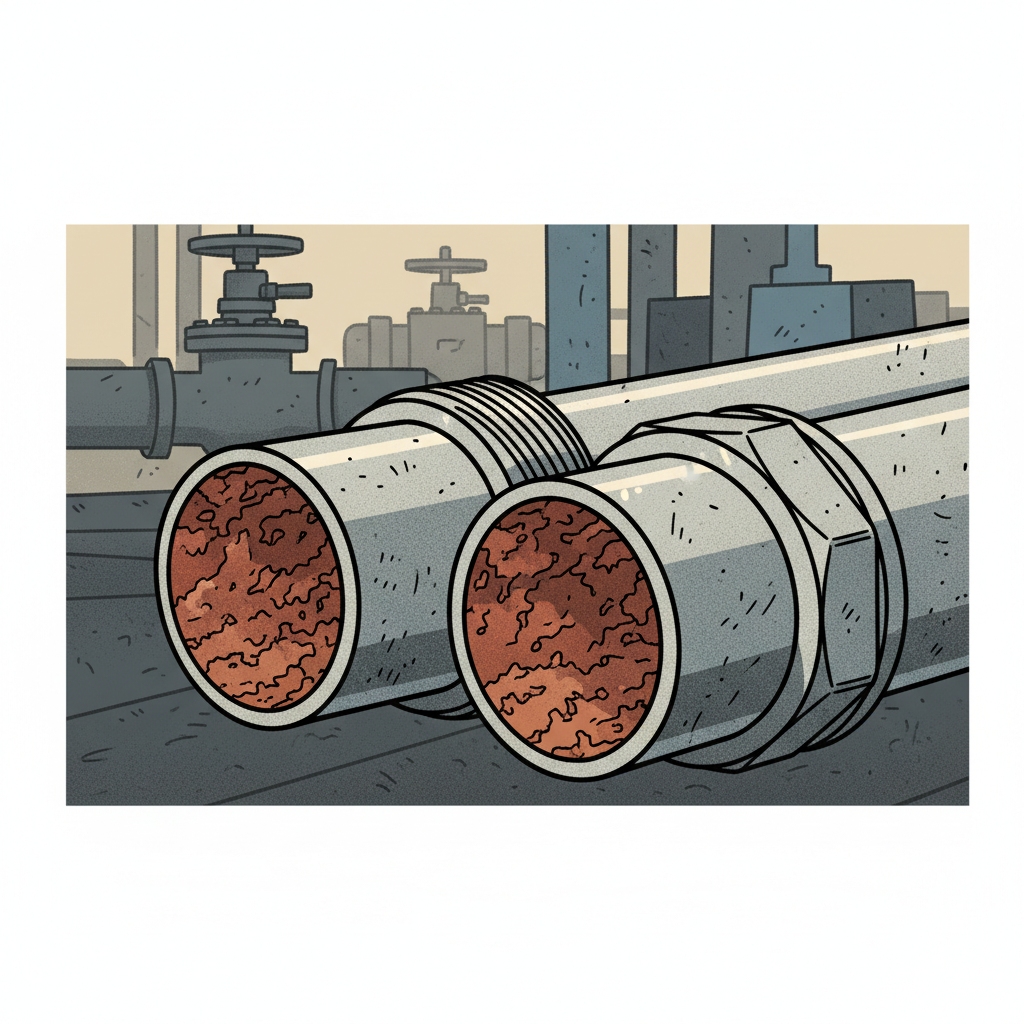

Galvanized iron, steel coated in zinc, was standard pre-1960s for its initial rust protection.

What Causes Galvanized Pipe Corrosion?

Zinc erodes over time, exposing iron to rust and restricting flow—reducing capacity by 50% after 20 years. This leads to low pressure you might notice in showers.

How to Spot Galvanized Pipes in Old Homes?

Threaded, dull gray pipes with a bumpy texture, often in basements. Shake for rattling if scaled inside.

Why Replace Galvanized with Modern Options?

It leaches contaminants, posing health risks. Upgrading to PEX boosts flow and safety—ROI in under five years via lower repairs.

Key Takeaways:

- Avoid for drinking water.

- Inspect annually in pre-1970 homes.

| Issue | Impact | Solution | |

|---|---|---|---|

| Corrosion | Flow Reduction | Replace with PEX | |

| Lifespan | 20-50 Years | Modern Plastics |

For visible lines, aesthetics matter.

What Role Does Chromed Copper Play in Water Pipes?

Chromed copper adds shine to exposed supply lines.

Why Use Chromed Copper for Exposed Lines?

Its polished finish resists tarnish, perfect for vanity areas. It maintains copper’s reliability without the patina.

How Does It Enhance Aesthetic Appeal?

Chrome plating mimics fixtures, blending seamlessly. You can install it confidently in open designs.

What Are Its Durability Limits?

Like plain copper, it risks pinholes but lasts 50 years. Not for buried use—surface-only.

Key Takeaways:

- Decorative upgrade.

- Compression fittings for easy swaps.

| Aspect | Chromed Copper | Plain Copper | |

|---|---|---|---|

| Appearance | Shiny | Dull Red | |

| Use | Exposed | Hidden |

Drainage relies on heavier options.

How Is Cast Iron Used in Water-Related Pipes?

Cast iron handles waste with quiet strength.

What Makes Cast Iron Sound-Deadening?

Its density muffles gurgling—ideal for multi-story homes. No echoes in walls.

Why Limit Cast Iron to Drain Lines?

Too brittle for supply; used for soil stacks. Modern codes favor it less due to weight.

How to Repair Cast Iron Sections?

Use no-hub couplings or PVC transitions. Professional cuts prevent cracks.

Key Takeaways:

- Superior noise control.

- 75+ year lifespan.

| Use | Pros | Cons | |

|---|---|---|---|

| Drains | Quiet, Strong | Heavy |

Seals tie it together.

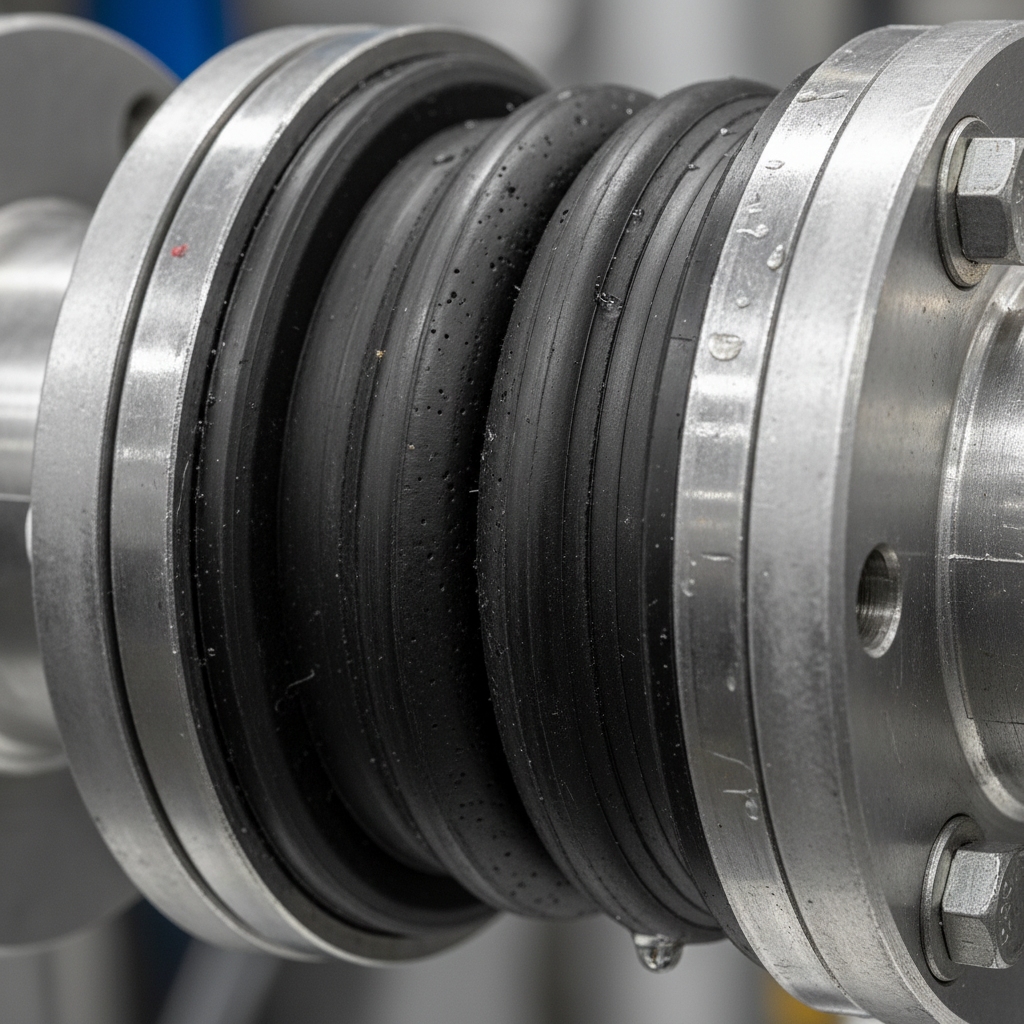

What Is Synthetic Rubber’s Use in Water Pipe Material?

Synthetic rubber provides flexible gaskets in joints.

How Does Synthetic Rubber Seal Connections?

EPDM variants compress to block leaks, handling -50°F to 300°F. Vibration-proof.

Why Is It Ideal for Flexible Joints?

Absorbs movement in earthquakes or settling homes. You gain peace of mind.

What Benefits for Pipe Flexibility?

Extends system life by 20% via reduced stress. Cost: $1 per seal.

Key Takeaways:

- Versatile for all materials.

- UV-resistant outdoors.

| Type | Temp Range | Application | |

|---|---|---|---|

| EPDM | Wide | Joints |

Ready to install? Here’s how.

How to Install Common Water Pipe Materials?

Proper setup ensures longevity—follow local codes.

What Tools Are Needed for PEX Install?

Crimpers, cutters, and expansion tools. Start with a manifold for even distribution.

Why Follow Codes for Copper Soldering?

Prevents fires; use lead-free flux. Torch evenly for strong bonds.

How to Avoid Leaks in PVC Joints?

Prime and glue in sequence—dry fit first. Cure 24 hours.

Key Takeaways:

- DIY PEX; pro for copper.

- Test pressure post-install.

| Material | Key Tool | Tip | |

|---|---|---|---|

| PEX | Crimper | Expand First | |

| Copper | Torch | Flux Evenly | |

| PVC | Glue | Prime Surfaces |

Looking ahead?

What Are Trends in Water Pipe Materials?

Innovation drives efficiency, and nowhere is that clearer than in modern piping systems. Across residential, commercial, and industrial projects, engineers now look beyond simple “does it carry water” requirements and focus on lifecycle cost, installation speed, safety, and environmental impact. Metals such as copper and steel still hold their place in high-temperature or specialty systems, but they lose ground where corrosion, weight, and theft risk cause headaches.

In their place, engineered plastics such as CPVC, PEX, and advanced PVC compounds continue gaining share because they balance performance with long-term operating stability. CPVC, in particular, stands out in hot and corrosive water environments where standard plastics struggle. Its ability to handle higher temperatures while resisting chlorinated water means designers can specify lighter systems, with fewer corrosion allowances and lower maintenance budgets, without sacrificing reliability.

As building codes evolve and more projects pursue energy- and water-efficiency certifications, demand shifts toward materials that support tight temperature control, reduced leakage rates, and stable performance over decades. That shift keeps CPVC firmly in the conversation, not just as a “PVC alternative,” but as one of the core materials in the future mix of water pipe technologies.

Why Shift to Eco-Friendly Plastics?

PEX and recycled PVC often cut carbon impact significantly compared with metals, because their production uses less energy and their lighter weight reduces transport emissions. But the story does not end there. CPVC plays an important role in this eco-focused transition, especially for hot and warm water systems where typical low-cost plastics cannot operate safely.

When they replace copper or galvanized steel in suitable applications, CPVC piping systems help lower overall embodied energy in a project while also reducing scale buildup and corrosion that can shorten service life. Longer lifespans mean fewer replacement cycles, less waste, and reduced resource use over the full life of a building or plant.

At the same time, more manufacturers now work on cleaner production routes, better additive packages, and recycling pathways for CPVC scraps and offcuts from fabrication. For specifiers trying to reach sustainability targets without risking performance, eco-conscious plastics strategy often looks like this: use high-temperature CPVC where heat, chlorination, or chemicals demand it; combine with PEX or standard PVC in cooler lines; and support recycling and responsible sourcing across suppliers. So the move toward “green” piping does not push CPVC aside. Instead, it positions CPVC as the reliable backbone material where safety, temperature, and chemical resistance cannot be compromised.

How Will Smart Pipes Evolve?

Sensors already appear in mains and high-value networks, where they monitor pressure, flow, and temperature to flag leaks early. Future smart piping pushes that intelligence closer to the fixture, integrating with building management systems and mobile apps so owners see alerts before damage spreads.

CPVC fits neatly into this evolution. Because CPVC systems are relatively easy to cut, join, and modify, contractors can incorporate sensor fittings, smart valves, and flow meters into both new and retrofit projects without rebuilding entire risers.

CPVC’s stability at elevated temperatures also means that temperature and pressure readings stay meaningful over time, without the drift that can come from deforming or degrading pipe walls. As more commercial and residential buildings adopt recirculating hot water loops, CPVC combined with smart controls can help maintain consistent temperatures, reduce stagnant zones, and cut unnecessary pump run-time.

Looking toward 2030, artificial intelligence and advanced analytics will likely sit on top of the data produced by these systems. That allows predictions of failure points, optimization of hot water schedules, and automatic fine-tuning of flow rates. In that landscape, CPVC becomes more than just a passive conduit; it becomes part of a smart, modular infrastructure where durable, heat-resistant plastic pairs with digital control layers to deliver safer, more efficient water management.

What Future for Hybrid Materials?

Hybrid strategies already gain traction, such as copper-PEX combinations that blend metal durability with plastic flexibility. In many projects, CPVC joins this mix as the high-performance hot water backbone.

For example, designers might specify CPVC for main hot-water risers and mechanical room manifolds, then transition to PEX branches in tight ceiling spaces or complex layouts. This approach balances pressure stability, temperature resistance, and ease of routing around obstacles. In industrial or commercial buildings, CPVC can also partner with stainless steel or lined carbon steel in zones that see chemical exposure, while still keeping weight and installation complexity lower than fully metallic networks. Forecasts showing rising adoption of hybrid piping strategies reflect a simple reality: no single material suits every condition across a large project. Instead, engineers choose from a palette—CPVC for hot, chlorinated, and mildly corrosive applications; PEX or PVC for cooler, low-pressure runs; metals where fire, impact, or extreme conditions demand them.

As more case studies validate the cost and reliability benefits of these mixed systems, adoption rates are likely to climb. In that future, CPVC remains a key “anchor” material that ties hybrid networks together, providing a stable, code-compliant, and long-lived core around which more flexible or specialized piping solutions can be arranged.

Key Takeaways:

- Greener options save resources.

- Tech enhances reliability.

| Trend | Benefit | Timeline | |

|---|---|---|---|

| Plastics | Low Impact | Now | |

| Smart | Predictive | 5 Years |

Conclusion

Choosing the right water pipe material affects safety, durability, and long-term system performance, and for many homeowners and project engineers, CPVC stands out because it handles hot water, resists corrosion, and delivers stable flow over decades with minimal maintenance. If you’re planning a new installation or upgrading an older system and want clear guidance on selecting the right CPVC grade or application design, feel free to contact us today for support.

FAQ

What is the most common water pipe material today?

Today, the most common water pipe materials are plastics such as PVC and especially CPVC for hot and potable water lines because they resist corrosion, install easily, and provide long service life.

How do I know if my pipes are PEX or copper?

PEX is flexible plastic (often red/blue); copper is rigid metal with a reddish sheen.

Can synthetic rubber replace traditional seals?

Yes, its durability suits most joints, improving flexibility over rigid alternatives.

Why avoid galvanized iron for new installs?

It corrodes quickly, restricting flow and risking contamination—opt for PEX instead.

What is the lifespan of common water pipe materials?

PEX and copper: 50-70 years; PVC/CPVC: 50+; galvanized: 20-50 (with corrosion).