Introduction

Industrial and marine environments are brutal on structural materials; moisture cracks concrete, and salts rust steel rapidly. 30 seconds too long ignoring this erosion, and you face catastrophic equipment failure. Here is the solution: Chlorinated rubber coatings provide a heavy-duty, impermeable shield that resists chemicals and water, ensuring your assets last for decades.

1. What Is Chlorinated Rubber Coating?

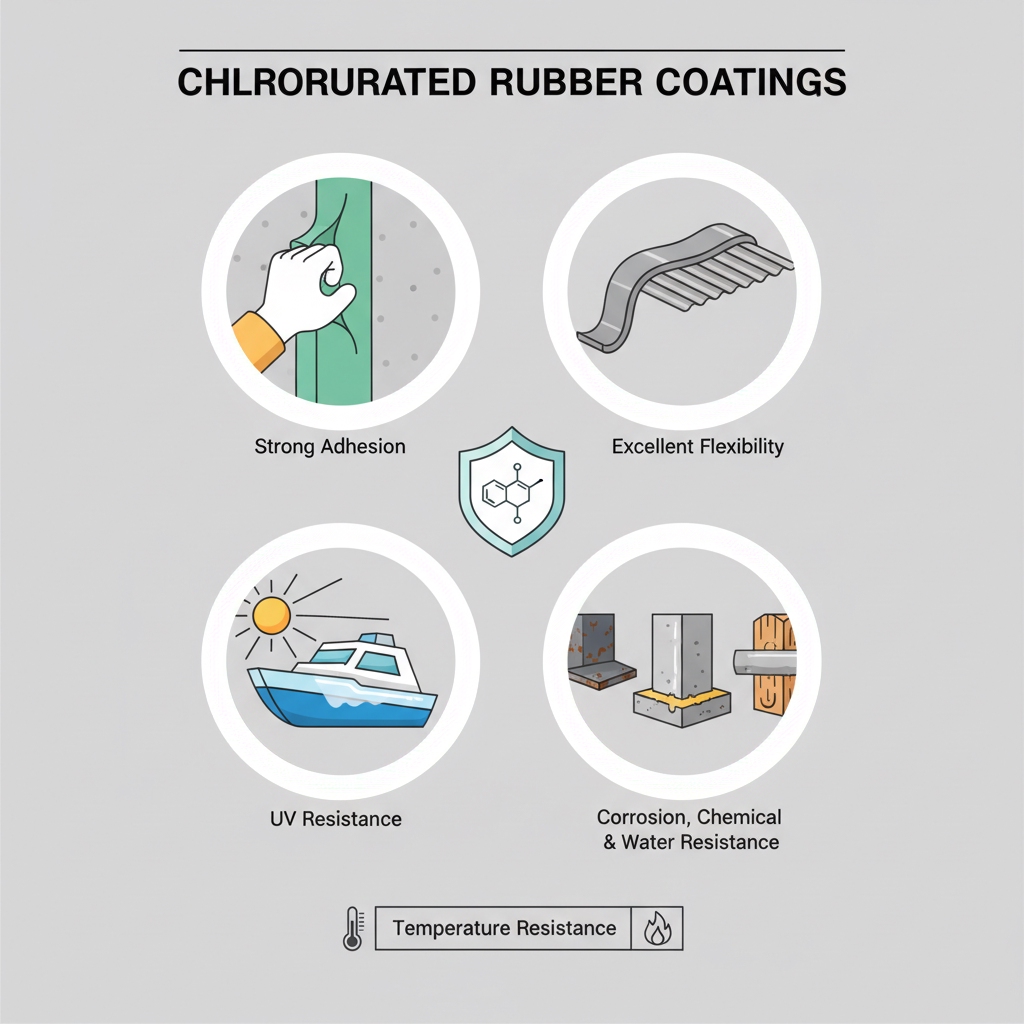

This coating is a high-performance binder created by modifying natural rubber with chlorine. But here is the thing: You are not just buying paint; you are utilizing a chemical modification designed for extreme resilience and high viscosity. This creates a solution that binds aggressively to substrates, trading elasticity for exceptional chemical inertness.

| Feature | Description | |

|---|---|---|

| Base Material | Chlorinated natural rubber | |

| Viscosity | Low to High | |

| Solubility | Aromatic hydrocarbons |

2. Why Use Chlorinated Rubber for Swimming Pools?

Swimming pools require a coating that withstands constant hydrostatic pressure and chemical exposure. You might be wondering: Why is this the gold standard? It is because it forms a continuous film that water simply cannot penetrate. It resists fungal growth and remains stable against pH fluctuations and chlorine attacks.

3. How Chlorinated Rubber Protects Marine Hulls?

Saltwater is the ultimate enemy of metal, causing rapid oxidation. Here is the deal: Chlorinated rubber effectively seals the steel from the electrolytes needed for rust to form. It provides a primary anti-corrosive layer for ships and docks, offering superior resistance to saline environments and UV exposure.

| Marine Application | Protection Type | |

|---|---|---|

| Ship Hulls | Anti-corrosive barrier | |

| Docks | Weather resistance | |

| Buoys | Immersion durability |

4. Can Chlorinated Rubber Save Industrial Tanks?

Industrial tanks face aggressive acids and alkalis that destroy standard coatings. What is the real story? Chlorinated rubber remains chemically inert, acting as a sacrificial liner that protects storage linings from broad-spectrum pH attacks. It is crucial for facilities handling aggressive industrial chemicals.

5. Is Chlorinated Rubber Best for Roof Sealing?

Roofs expand and contract with temperature changes, which often cracks rigid paints. This is where it gets interesting: This rubber-based composition maintains elasticity, moving with the building to prevent thermal shock damage. It creates a seamless membrane that resists ponding water and moisture intrusion effectively.

| Roof Issue | Solution | |

|---|---|---|

| Thermal Movement | Flexibility prevents cracking | |

| Standing Water | Total impermeability | |

| UV Exposure | Long-term stability |

6. Why Apply Chlorinated Rubber to Road Markings?

Speed is critical in road maintenance. Ready for the good part? You can reopen a road to traffic almost immediately because the solvent evaporates incredibly fast. Beyond speed, it offers excellent abrasion resistance, retaining reflective beads even under heavy tyre friction and traffic.

7. Does Chlorinated Rubber Stop Chemical Corrosion?

Corrosion requires oxygen and moisture to progress. Let us look closer: This coating creates a dense molecular wall with low permeability and high dielectric strength. It acts as a universal anti-corrosive solution for structural steel, effectively isolating the metal from atmospheric threats.

| Threat | Protection | |

|---|---|---|

| Humidity | Vapor barrier | |

| Acid Rain | Chemical inertness | |

| Salt Spray | Electrolyte blocking |

8. How Chlorinated Rubber Seals Concrete Floors?

Concrete floors in warehouses generate dust and absorb hazardous spills. Think about this: Coating the floor creates a non-porous, hygienic surface that resists oil penetration. It handles heavy forklift traffic and impact without gouging, making decontamination simple and effective.

9. Is Chlorinated Rubber Used in Adhesives?

Beyond protective coatings, this material is versatile. It gets better: High-viscosity variants act as powerful bonding agents for joining dissimilar materials like rubber and steel. It is a critical ingredient in heavy-duty adhesives used in automotive assembly and conveyor belt repairs.

| Property | Benefit | |

|---|---|---|

| Tack Strength | High initial grab | |

| Flexibility | Bond resists brittleness | |

| Compatibility | Blends with synthetic rubbers |

10. What Are the Pros of Chlorinated Rubber Upkeep?

Maintenance costs can cripple a budget, but this system is different. The bottom line is: New coats fuse chemically with old coats through a “solvent bite,” eliminating the need for expensive abrasive blasting. The film remains permanently soluble in its own solvents, allowing for seamless repairs.

Conclusion

Chlorinated rubber coatings offer a robust solution for corrosion, chemical attack, and water damage. By specifying this material, you ensure infrastructure longevity and reduced maintenance costs. Do not let rust win; evaluate your assets today and choose chlorinated rubber for superior protection.

FAQ

Q1: Can I apply chlorinated rubber over old paint systems?No, usually not. The strong solvents will likely lift or dissolve conventional paints; apply over bare substrates or existing chlorinated rubber.

Q2: What is the best way to thin chlorinated rubber paint?Use high-aromatic solvents. Specific thinners like Xylene are required, as standard mineral spirits cannot dissolve the resin.

Q3: How do I know if my existing pool paint is chlorinated rubber?Perform a solvent test. Rub the surface with Xylene; if it becomes sticky, it is likely chlorinated rubber.

Q4: Can I use spray equipment to apply these coatings?Yes, absolutely. Airless spray is preferred for uniform thickness, provided equipment seals are solvent-compatible.

Q5: Is chlorinated rubber paint breathable?No, it is not. It creates an impermeable vapor barrier, which is excellent for waterproofing but prevents moisture release.